Electrical Energy Consumption Meter Guide with Smart Accurate Features

Discover Liuyi Electric’s precise electrical energy consumption meters with advanced accuracy, smart monitoring, and reliable industrial-grade performance.

Read More

Have you ever stood in front of a new piece of industrial equipment and realized your building only has single-phase supply? If so, you are not alone. Many commercial and light industrial facilities face the same challenge. The good news is that 3 phase power from single phase is not only possible, it is widely used across manufacturing, HVAC, and automation environments.

In this article, we will walk through what converting single-phase to three-phase power really involves, why businesses do it, and how you can decide on the right approach for your operation.

Before we talk about conversion, let’s address the obvious question: why bother?

Three-phase power delivers electricity more efficiently than single-phase. It provides smoother torque, higher power density, and better performance for heavy loads. That is why most industrial motors, compressors, pumps, and CNC machines are designed for three-phase input.

If your facility only has single-phase service, you may encounter limits such as:

This is where 3 phase power from single phase becomes a practical workaround rather than a costly utility upgrade.

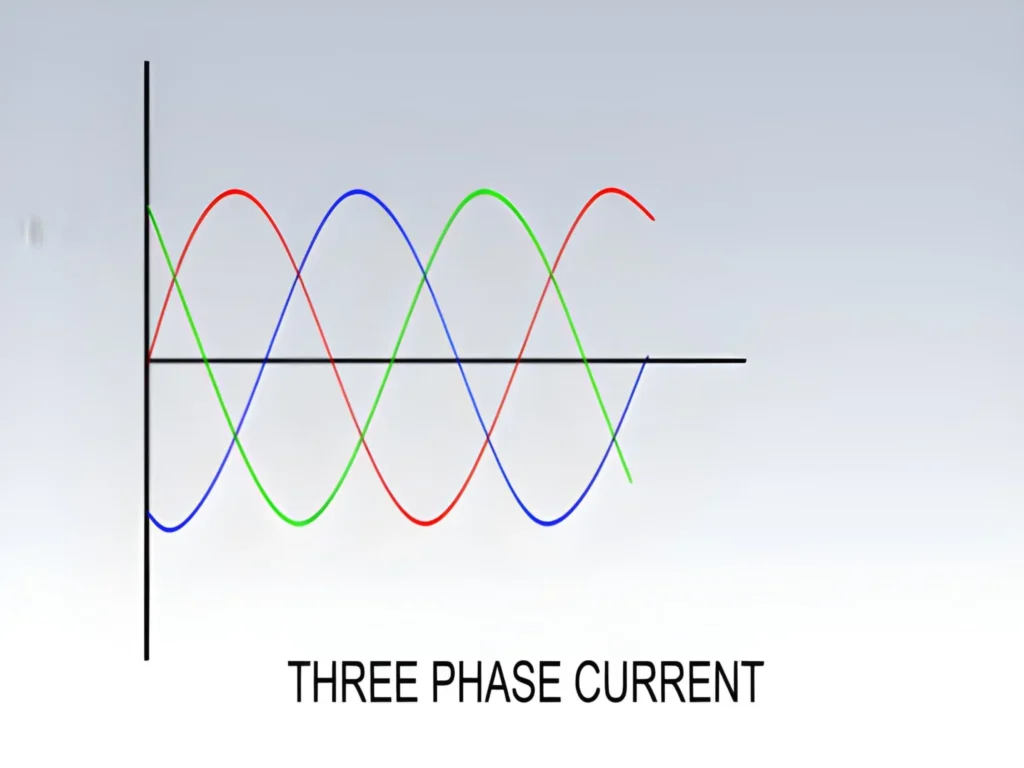

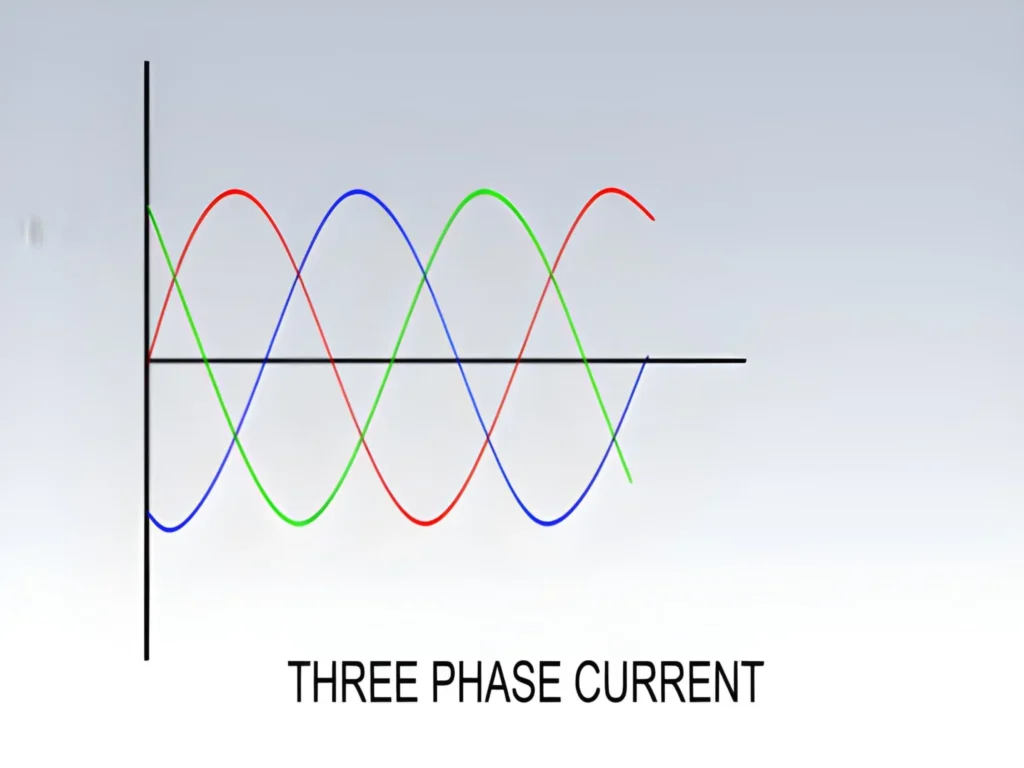

single-phase vs three-phase power, at a basic level, the difference lies in how electricity is delivered.

Single-phase power uses one alternating voltage waveform. Three-phase power uses three waveforms, offset by 120 degrees. This creates a continuous and balanced power flow.

Here is a simple comparison to clarify the difference:

| Feature | Single-phase power | Three-phase power |

|---|---|---|

| Typical voltage | 120V / 240V | 208V / 400V / 480V |

| Power stability | Pulsating | Smooth and continuous |

| Motor efficiency | Lower | Higher |

| Common use cases | Homes, small offices | Factories, data centers |

This difference explains why converting to three-phase power can unlock higher performance without changing your entire electrical infrastructure.

Converting single-phase to three-phase does not magically change your utility supply. Instead, it uses specialized equipment to simulate or generate a three-phase output.

There are three primary methods used in the field.

Static converters are the simplest option. They use capacitors to start a three-phase motor and then drop out of the circuit.

They are inexpensive and easy to install, but they come with trade-offs:

Static converters may work for small motors, but they are rarely ideal for continuous industrial use.

Rotary phase converters use a rotating idler motor to generate the third phase.

They are more robust than static converters and can support multiple machines at once. However, they also:

For workshops with mixed loads, rotary systems are still common, though newer technologies are replacing them.

Modern solutions rely on solid-state electronics. Digital phase converters and variable frequency drives (VFDs) electronically create balanced three-phase power from a single-phase input.

Key advantages include:

This approach is increasingly preferred when implementing 3 phase power from single phase in professional environments.

You might be surprised how often this conversion is used.

Common applications include:

In many retrofit projects, converting power locally is far more cost-effective than requesting a new three-phase service from the utility company.

When planning a conversion, specifications matter. Choosing the wrong ratings can lead to downtime or equipment damage.

Here are the most important parameters to review:

| Specification | Why it matters |

|---|---|

| Input voltage | Must match your single-phase supply |

| Output voltage | Must match equipment requirements |

| Power rating (kW or HP) | Determines load capacity |

| Frequency (50/60 Hz) | Affects motor speed and performance |

| Efficiency | Impacts operating cost |

A properly sized system ensures that your 3 phase power from single phase solution performs reliably over the long term.

Today’s digital converters and VFDs offer more than just power conversion.

Many include smart features such as:

These features allow you to monitor consumption, detect inefficiencies, and support compliance reporting. For energy-conscious facilities, this added visibility is a major advantage.

Cost is always part of the decision.

While static converters are cheap upfront, they may cost more over time due to inefficiency and equipment wear. Digital systems have higher initial prices but often deliver faster return on investment through:

When evaluating 3 phase power from single phase, it is worth looking beyond the purchase price and focusing on lifecycle cost.

If you are unsure how to calculate ROI for your specific load profile, this is a good point to contact us for a quick technical discussion or request a tailored quotation.

Electrical safety should never be an afterthought.

Any conversion system must comply with local electrical codes and standards. This includes proper grounding, overcurrent protection, and enclosure ratings.

In regulated industries, accurate power measurement is also critical. Integrating certified electric power meters ensures compliance with internal audits and external inspections.

Working with qualified electricians and engineers is strongly recommended when deploying these systems.

If your operation is limited by single-phase service, you are not stuck. 3 phase power from single phase offers a proven and flexible way to run industrial equipment without major infrastructure changes.

By understanding the available technologies, evaluating specifications carefully, and considering long-term costs, you can make a confident and informed decision. Whether you are powering motors, HVAC systems, or monitoring energy with advanced electric power meters, the right solution can unlock performance you may not have thought possible.

If you are exploring options or want expert input tailored to your application, we are always ready to help you take the next step with confidence.

Yes. Modern three-phase electric power meters are designed to measure voltage, current, power, and energy accurately, even when the source is converted from single-phase supply.

With digital phase converters or VFDs, the answer is yes. These systems provide stable and efficient output suitable for continuous operation.

You should use a true three-phase power meter. It provides accurate readings for balanced and unbalanced loads and supports energy monitoring and reporting.

Properly designed systems can actually extend motor life by delivering stable voltage and frequency, reducing thermal stress.

Not necessarily. Utility upgrades can be expensive and time-consuming. In many cases, local conversion offers faster deployment and lower overall cost.